Tool & Die Fabrication

Mould and die fabrication is the foundation of any plastics production process and is of high demand in the global marketplace. Modern-day machine tooling depends on time-to-market with the increasing requirement for automation and loading, with repeating tolerances in the regions of microns.

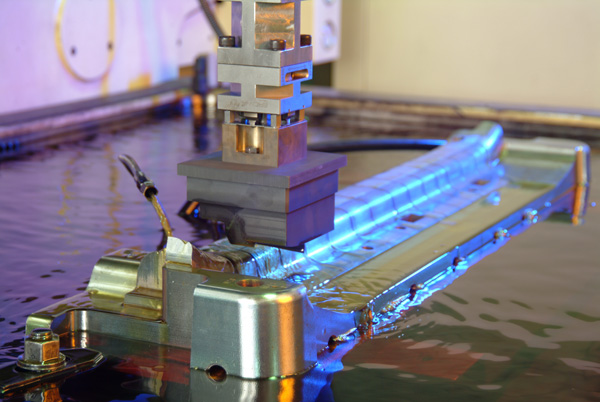

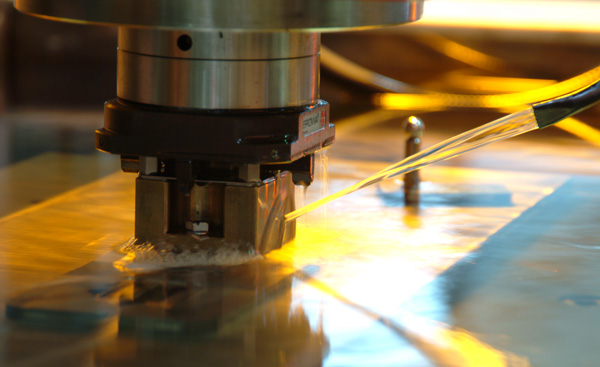

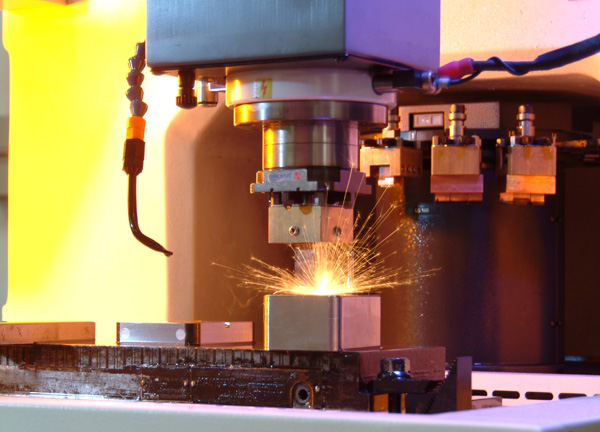

SKP's tool & die fabrication division consists of a team highly-trained and skilled tool designers, engineers, and makers. With the aid of fully-integrated CAD/CAM systems, our line-up of die/mould vertical machining centres, graphite milling, and wire and sinker EDM specialise in reducing and even eliminating polishing time.

To ensure the best in quality delivery, our partners include Mori Seiki for machining centres, Deckel Maho for multi-tasking turning centres, Makino for drilling and wire EDM, and dozens of other leading suppliers that provide full automation, precision tooling, top-notch fixtures, and quality control. This gives SKP a mould-making capacity of approximately 500 moulds per year – each of them a pride of our stringent fabrication process and quality control.

Our Hardware

- Makino CNC Machinery

- Makino copy milling & digitising

- Makino machining centre

- Makino Graphite EDM machinery

- Makino CNC Wire Cut machinery

- Deckel Maho Universal CNC Machinery (5-axis)

- Mori Seiki CNC machining centre

Our Software

- Pro Engineer

- Unigraphics

- Solidworks

- Top Solid

- AutoCAD

- Delcam power shape / Mill Solution

- MasterCam

Mould & Die Fabrication

- High Precision Mould From 50 Tons – 2000 Tons

- Dual Shots

- Gas Assist

- E Mould Systems

- Heat And Cool Sytems

Precision Machining

Our state-of- the-art machining tools are at your disposal, able to provide you with the competitive edge for any type of application you require.

Flexible Manufacturing System

You can trust us to create the specialised solutions you need. Our experience team of machinists and highly advanced equipment enables us to manufacture a complete range of precision machined components across diverse industries.

Multi-Material Applications

We manufacture a myriad of turnkey products. Our sub-assemblies are capable of machining aluminium, stainless steel, copper, magnesium, molybdenum, ferrous and nonferrous steels, high-tech plastics, nickel and high-nickel alloys, castings, forgings and many others.

Our Precision Machining Capabilities consist of:

- Multi-Pallet Horizontal Flexible Manufacturing System

- 5–Axis CNC Milling, Horizontal CNC Milling, Vertical CNC Milling, CNC Turning

- Complex Electro-Mechanical assembly and test

- Manufacture parts from a variety of materials, including aluminum, titanium, copper, molybdenum, stainless steel

- Medium to large size format - typical size range 6" to 80" (15cm to 200cm)